You need solid and durable concrete, but you don't want

to hassle with the expensive procurement, transportation, and crane installation of the rebar mesh, do you…

to search for reliable workforce who actually understand their job?

to repair cracks in the concrete?

to be afraid that the end result will be terrible.

What is macro fibre?

The technique has been used in the construction industry for several decades to reinforce concrete – and now it’s available in your home too!

Replacing traditional rebar mesh with fiber-reinforced concrete makes the work simpler, faster, and more cost-effective, resulting in a much more durable end product.

It’s a plastic fiber made of polypropylene, with very high tensile strength, 40-50 mm in length, and 0.5 mm thick, which you can mix into the concrete in the concrete mixer to make the end result stronger and more durable.

How much does it cost?

Both products are high-quality structural macro fibers with the same function. The choice is yours; you can choose which one you prefer.

What can it be used for?

You can easily get it from us.

You can replace steel mesh with structural macro fibers when its function is load distribution and crack prevention. For load-bearing structural elements like beams, self-supporting slabs, and stairs, involving a structural engineer is necessary to use structural macro fibers. There are already several existing examples of this.

How does it work?

1. Concrete Mixing

Add the components of concrete (cement, aggregate, water, and additives) to the mixer.

2. Adding structural macro fibers

Add the structural fibers to the concrete in a quantity of 2-6 kg/m³, depending on its desired performance.

3. Mixing structural macro fibers

Mix for a few minutes – Before pouring, mix for 1 minute per cubic meter in a mixer truck or 2 minutes in a concrete mixer at full speed.

4. Application

You can use it immediately afterward

It’s simple, isn’t it? You can download the infographic from here to help.

What are the advantages of macro-fiber reinforced concrete?

(Tap the card for more information)

Simplier ⟶

No more trucking, craning, bending, tying and other work that involves reinforcing steel mesh.

Cheaper⟶

You can save more than 340 EUR when concreting a 10 cm thick carport of 100 sqm compared to using a reinforcing steel mesh! Use the calculator to work out how much you need!

More durable ⟶

The end result will be tougher and more durable, as you can see in the video. With fiber-reinforced concrete, you can also reduce cracking from shrinkage to zero during curing.

Faster⟶

You can significantly reduce construction time since the labor required is almost zero compared to using reinforcing steel mesh.

Easier⟶

“For an average load of 10 m³ of concrete work, you’ll only need 30-40 kg of macro mesh, so there’s no need to worry about transporting it—unlike the over 500 kg required for reinforcing steel mesh.”

Smaller ecological footprint ⟶

40 kg of concrete reinforced with static macro fibers can replace 500 kg of reinforcing steel. This marks not only a substantial difference in weight but also holds environmental benefits, reducing carbon dioxide emissions by 70%.

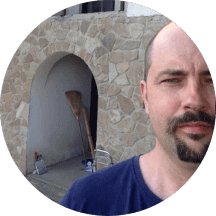

About Us

You’re already familiar with fiber-reinforced concrete, but you may not be familiar with us.

I’m Levente Siposs, the owner of Levron Ltd., the creator of Betonbooster, and a dedicated advocate of fiber-reinforced concrete.

This website was created to make this technology accessible to everyone.

I am convinced that you also need access to the product that will change our views on concrete work, making it not only much easier but also more affordable.

This product will have the same impact on concrete work as Velcro did on humanity when it emerged from space exploration.

A diligent team is working behind the scenes to simplify concrete work for you and deliver the macro fibers to you in the shortest possible time.

REFERENCES

Fiber-reinforced concrete has already proven itself in numerous places. Here are some examples:

How much does it cost?

Both products are high-quality structural macro fibers with the same function. The choice is yours; you can choose which one you prefer.

AND HOW MUCH DO YOU WIN WITH IT?

When creating a 100 m², 10 cm thick driveway with classic rebar mesh, you will need:

| 10 sheets of 6x100x100 welded rebar mesh | 607 € |

| Shipping cost | 65 € |

| Approximately for laying, tying, and spacer-related work: | 31 € |

The same work with ArmoTec is this much cheaper:

| 40 kg of macro fibers, priced at 9,99 €/kg | 399,6 € |

| Shipping cost | Free |

| Approximately for laying, tying, and spacer-related work: | 0 € |

Better spend this money on yourself!

The calculation does not include the price of concrete!

Delivery is free for orders over 129 EUR. Below this quantity, there is a courier fee 10 EUR.

What is the guarantee?

All three products have a construction industry permit valid throughout Europe.

They can bear the CE marking and can be placed on the market with a Declaration of Performance.

The manufacturers take full responsibility to ensure that the technical parameters of their macro fibers match the technical data stated in the Declaration of Performance and the product Technical Data Sheet.

The concrete-macro fiber composite meets the values required by the EN 14889-2 standard.

The User may use the product solely at their own risk and acknowledges that the Manufacturer is not liable for financial or non-financial damages resulting from improper use.

Frequently Asked Questions

What type of concrete can the macro fiber be mixed with?

You can mix the macro fiber with a minimum C12 strength class concrete.

- This can be bagged concrete purchased from the store, known as dry mix concrete, or screed concrete.

- It can be concrete made at home from aggregate, cement, and water.

- It can be concrete purchased from a concrete plant.

- It can be concrete prepared using an esztichboy (a concrete mixer with a pump).

It’s not recommended to mix it with:

- Lightweight concrete made with polystyrene beads or perlite because it lacks sufficient strength.

- CKT concrete (cement-bound load-bearing base layer) because it is also not sufficiently strong, and it is not intended to be.

How much macro fiber should I order?

The dosage of macro fibers depends on the function and thickness of the concrete. Click here to calculate it using our calculator: Calculator

What is the minimum concrete thickness when using macro fibers?

Our macro fibers have a length between 40-50 mm. Therefore, they can mix perfectly in concrete that is only 5 cm thick. However, we have also created a 2 cm thick test piece, and it significantly increased its load-bearing capacity. Watch the video about it here:

However, we do not recommend concrete layers thinner than 3 cm; for these, it is advisable to use special concrete, for example: Baumit Flexbeton

When can't it be used to replace rebar mesh?

In general, structural macro fibers are used to replace rebar mesh when its function is crack prevention and load distribution.

They cannot be used to replace rebar mesh in self-supporting structural elements because the reinforcement of such structures is complex, and the reinforcement serves a function beyond load distribution. These include:

Raft foundation

Slab

Ring beam

Self-supporting stairs

Cantilever

Column

Retaining wall

Pillars

Can it be used with underfloor heating?

Yes, it is particularly useful. It prevents damage caused by the regular thermal expansion during underfloor heating.

IMPORTANT!

The rules of the first heating process must be followed! Heating cannot begin within 14 days, and the surface cannot be covered before the entire heating process.

Why is it cheaper when the price of a 4mm steel mesh is only this much?

A 4mm steel mesh costs 18 EUR in the spring of 2023. For a 10 cm thick concrete slab, which can even carry the weight of a truck, it is advisable to use at least a 6mm mesh with a 100×100 grid spacing. You can’t even walk on the 4mm mesh during the concrete pouring.

A 6mm 100×100 mesh costs 60 EUR at the same time. Its price per square meter is 6 EUR, and this does not include the cost of transportation and installation.

With ArmoTec priced at 10,90 EUR, if you use it in the concrete at a dosage of 4 kg/m³, it can replace this 6mm mesh. The price per square meter for ArmoTec in a 10 cm thick concrete is 4,3 EUR.

This is why we say it is cheaper than steel mesh.

If you use a 4mm mesh in the concrete, it is only good for crack prevention. For that purpose, 2 kg of ArmoTec at 2 EUR/per square meter is sufficient. At least you won’t have the hassle…

Can I use it to replace steel in raft foundations or ring beams?

No.

You can use ArmoTec to replace steel when it is rebar mesh, and its purpose is crack prevention and load distribution.

You can use it for these tasks:

Screed concrete

Subfloor concrete

Slab foundation (for lightweight structures, garages)

Sidewalk

Pavement

Driveway

Pergola

Ground-level stairs

There is a type of fiber where only 1 kg is needed. Why do I need more of this?

The fiber that only requires ‘1 kg’ is fibrillated fiber. It doesn’t have a structural role, and it doesn’t contribute to the reinforcement of concrete. Its purpose is to reduce the likelihood of cracking during concrete curing and enhance the fire resistance of the cured concrete.

ArmoTec can achieve all these functions but also significantly strengthens the concrete, increasing its load-bearing capacity, durability, and it can replace steel mesh.

Is it easy to smooth out?

Yes, the surface of fiber-reinforced concrete can be easily smoothed out. The fibers can be easily embedded into the fresh concrete. If there are any protruding fibers left after the concrete has cured, they can be easily removed using a propane torch.

Negative feedback: 0

Customer reviews

“The contractor initially argued in favor of using steel. However, considerations such as static factors, the more favorable cost compared to steel, and the numerous labor-intensive tasks involved in the cumbersome transportation, loading, and bending of steel eventually convinced us to choose macro fibers. These fibers mixed perfectly in the concrete during the process, and their application with the pump into the formwork went smoothly. We saved a significant amount, approximately three to four times the cost of steel reinforcement. The manager of the concrete plant mentioned that they regularly use macro fiber reinforcement, reassuring us about its durability and strength. I highly recommend it to anyone in the construction process.”

Karsay Koppány

“The steel mesh in my mind was as inseparable from concrete pouring as foam is to beer. The only difference is that I like the foam on my beer, but I don’t enjoy installing the mesh before pouring concrete. I never thought there could be another solution until I encountered structural macro fibers. It’s a game-changer in today’s world, especially when finding labor for heavy manual work is challenging. There’s no need to carry, tie, or adjust. The time spent on steel installation completely disappears. You just throw the necessary amount into the mixer, and it’s done. While it may not be suitable for load-bearing structures, it’s perfect for everything else: driveways, base concrete, foundations. For such jobs, this is the only thing I use.”

“The steel mesh in my mind was as inseparable from concrete pouring as foam is to beer. The only difference is that I like the foam on my beer, but I don’t enjoy installing the mesh before pouring concrete. I never thought there could be another solution until I encountered structural macro fibers. It’s a game-changer in today’s world, especially when finding labor for heavy manual work is challenging. There’s no need to carry, tie, or adjust. The time spent on steel installation completely disappears. You just throw the necessary amount into the mixer, and it’s done. While it may not be suitable for load-bearing structures, it’s perfect for everything else: driveways, base concrete, foundations. For such jobs, this is the only thing I use.”

Szabolcs

“It wasn’t easy to believe that these small fibers could strengthen concrete like this. However, the fracture tests speak for themselves, and the video clearly shows what this material is capable of. I’ve worked with steel mesh many times because I didn’t know there was a much better, cheaper, and simpler solution. In my latest concrete pouring, I used structural macro fibers, and the difference was astonishing in how much less effort this material requires compared to concrete mesh. I simply tossed it into the concrete mixer, and three minutes later, I poured the concrete, which essentially already had the reinforcement in it. No struggling with cutting, folding, tying, or supporting on the job site. It’s the best invention for concrete work.”

“It wasn’t easy to believe that these small fibers could strengthen concrete like this. However, the fracture tests speak for themselves, and the video clearly shows what this material is capable of. I’ve worked with steel mesh many times because I didn’t know there was a much better, cheaper, and simpler solution. In my latest concrete pouring, I used structural macro fibers, and the difference was astonishing in how much less effort this material requires compared to concrete mesh. I simply tossed it into the concrete mixer, and three minutes later, I poured the concrete, which essentially already had the reinforcement in it. No struggling with cutting, folding, tying, or supporting on the job site. It’s the best invention for concrete work.”

Szűcs Attila

“Using macro fibers made concrete pouring much easier and faster than using steel mesh. I had to bring the rolled-up steel mesh from the supplier, and it was a challenge to flatten it at home enough to use. Even after straightening it, I had to support it in several places so that the concrete could flow underneath, but it still ended up quite wavy. With macro fibers, all these problems disappeared. I simply added a few handfuls of fibers to each mix, which equates to a quantity of 3 kg/m³. After two minutes of mixing, the exceptionally strong concrete was ready. There surely isn’t anything simpler than this.”

“Using macro fibers made concrete pouring much easier and faster than using steel mesh. I had to bring the rolled-up steel mesh from the supplier, and it was a challenge to flatten it at home enough to use. Even after straightening it, I had to support it in several places so that the concrete could flow underneath, but it still ended up quite wavy. With macro fibers, all these problems disappeared. I simply added a few handfuls of fibers to each mix, which equates to a quantity of 3 kg/m³. After two minutes of mixing, the exceptionally strong concrete was ready. There surely isn’t anything simpler than this.”

Benyák Adrián