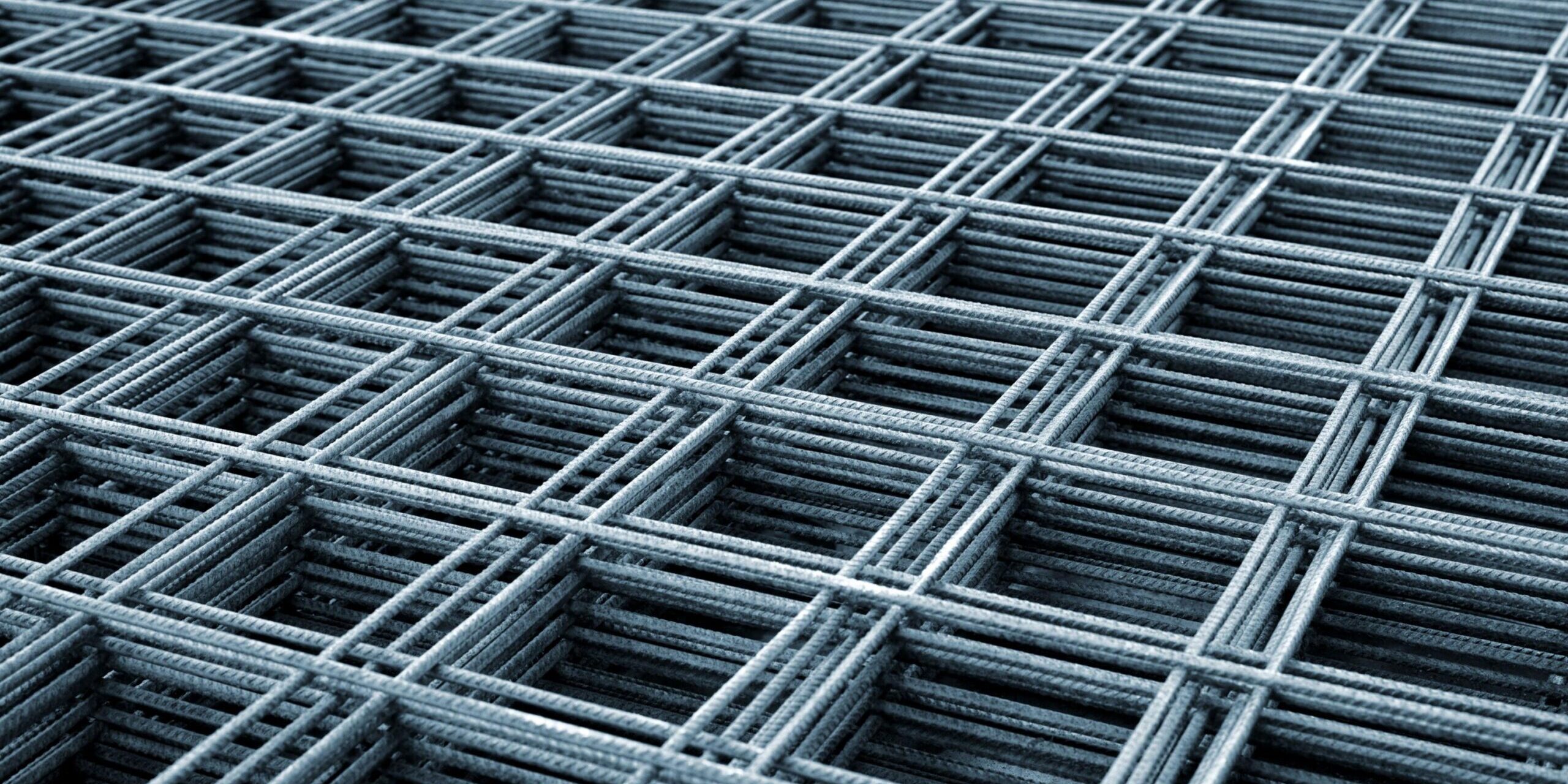

Why is it necessary to use concrete mesh?

Because while concrete has very good compressive strength, its tensile and flexural strengths are lower. However, concrete structures typically experience all three forces, so we use concrete mesh to increase tensile and flexural strength and reinforce larger areas of concrete surfaces.

Steel has been used for reinforcing concrete since the 1800s.

In many cases, when we do concrete work at home, we immediately think of using mesh reinforcement or welded mesh, which needs to be placed inside the concrete.

- concrete slab

- setting concrete

- base concrete

- sidewalk

- driveway

- pit

- pergola

- filling of formwork blocks

- staircase

- etc.

We believe concrete is eternal, yet we often see surfaces like these:

We want to avoid this condition, so we put concrete mesh in the concrete.

Advantages of concrete mesh:

- reinforces concrete, especially its tensile and flexural strength,

- accessible to almost anyone,

- has been proving its adequacy for two centuries,

- available in large quantities,

- reduces the tendency of concrete to crack,

- provides employment for many people worldwide in both manufacturing and installation.

There are several disadvantages that must be taken into account:

- Transporting concrete mesh is expensive due to its heavy weight.

- due to its large size, a large-sized truck is needed even if only 1-2 pieces are needed,

- corrodes,

- its production brutally pollutes the environment,

- loading and assembly require heavy physical work,

- storage is not feasible everywhere,

- its assembly is labor-intensive and slow,

- poses a risk of accidents,

- its price is increasingly expensive,

- it drives huge financial profits for large corporations, making it very difficult to avoid.

Alright, but what can we do to avoid the disadvantages of the concrete mesh and still have strong concrete?

Let’s prepare fiber-reinforced concrete!

The reinforcement of concrete with various fibers dates back to the Roman era. However, the real breakthrough began 2-3 decades ago when concrete industry experts started developing various synthetic fibers. These fibers have been used and developed for decades. You can read more about it here: Substituting concrete steel with static macro fibers.

Do these structural macro fibers really provide as much strength as the steel mesh?

And much more!

- They enhance the tensile and flexural strength of concrete,

- almost anyone can access them (now) here.

- available in large quantities, there is no shortage of them,

- their price depends on raw materials, but transportation costs do not affect their price as much as steel,

What is it that it cannot do, but the welded mesh can?

- It has not been proven for two centuries, only for two decades,

- It does not provide as many jobs as the production of concrete steel mesh.

What can the structural macro fiber do that the concrete steel mesh cannot?

- Due to its light weight, the shipping cost is very low,

- due to its small size, it can be transported in the trunk, in an amount sufficient to reinforce 20 m3 of concrete, instead of 1000 kg of steel,

- it does not corrode, so much more durable concrete can be made with it, and it does not deteriorate,

- it strengthens the concrete in three dimensions, not in two dimensions like the steel mesh,

- it pollutes the environment much less than the steel mesh, its ecological footprint is 70% smaller already during production,

- it is easy to load and can be stored anywhere,

- its installation requires zero labor, significantly speeding up construction,

- it is not at all hazardous,

- small businesses can manufacture it just as well as large ones, so our money does not go to the largest industrial companies, but we strengthen the small ones.

And a few more advantages I haven’t mentioned yet:

- In most cases, it is cheaper than the mesh,

- increases the waterproofing of concrete,

- increases resistance to aggressive substances such as road salt, chemicals,

- enhances the fire resistance of concrete.

Moreover, it can be with you in just two days

Ordering ArmoTec is simpler than ordering a drill online. There’s no need to research, no various sizes to consider. You simply add the required quantity to your cart, fill out the shipping and billing information, and you’re done. The courier picks it up the next day, and it’s delivered the following working day.

Initially, people were hesitant to use Edison’s light bulbs because they were afraid of electricity. We were reluctant to fly for decades after the invention of the airplane. Now we can’t imagine life without these innovations.

Structural macro fibers revolutionize concrete work, and now they’re accessible to everyone.

Come, order it here in just 2 minutes: ArmoTec

Siposs Levente

Renovation Expert

A Dedicated Advocate for Sustainable Renovations