The most well-known additives for fiber-reinforced concretes are steel fiber, steel wire, glass fiber, macrofiber, and microfibers.

The addition of fibers to concrete is not a recent invention. It has been used for decades, and it’s a continuously evolving innovation.

However, it’s worth seeing clearly before deciding what we need.

The use of fibers in concrete is regulated by the MSZ EN 14889 standard. Part 1 pertains to steel fibers, while Part 2 covers synthetic fibers.

What do we need to know about fibers briefly?

In general, fibers can be divided into two main groups:

- AThe fibers that reduce cracks resulting from the shrinkage of fresh concrete.

- The fibers that increase the residual tensile strength of hardened concrete.

The latter generally meet both requirements.

Microfibers (fibers thinner than 0.3 mm) are not statically dimensionable and have no effect on the residual strength of concrete.

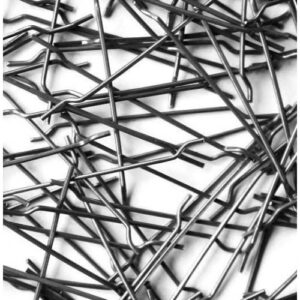

Steel fibers

A thin steel wire that reduces the susceptibility to shrinkage cracking. Unfortunately, it corrodes easily, is prone to clumping, and requires a relatively large quantity to be effective. However, this can lead to small hedgehogs forming in the concrete, damaging not only the concrete mixer, mixer truck, or concrete pump, but also resulting in uneven distribution in the concrete, casting doubt on the final outcome. Check it out here

Glass fibers

They are mainly used to reduce shrinkage cracks that occur during the curing of concrete. They do not corrode and are lightweight. However, they cannot be statically sized, and they do not improve the final strength values of the concrete.

Monofilament fibers

They serve a similar purpose to glass fibers in preventing cracks resulting from initial shrinkage

Fibrillated fibers

A microfiber made using a special process, which cannot be statically sized, but in certain cases, it may be suitable for replacing traditional steel reinforcement.

Structurally dimensionable fibers that also increase the residual tensile-flexural strength of concrete and reduce or eliminate the formation of cracks resulting from initial shrinkage.

Steel fibers

They enhance most properties of concrete. They have a very positive effect on tensile-flexural strength, load-bearing capacity, and fatigue strength

Their disadvantage is that they corrode and can damage vehicle tires. Corrosion-resistant versions are very expensive. Mixing them is cumbersome and can damage concrete mixing equipment. Their distribution in the concrete mix is not always uniform, and clumping is likely

Macro fibers

High-performance synthetic fibers with a minimum diameter of 0.3 mm and lengths ranging from 20 to 60 mm. Adding them to concrete significantly increases the lifespan, toughness, and residual tensile-flexural strength of concrete. Their surface is either ribbed or wavy, which enhances their resistance to pull-out.

It can replace steel mesh reinforcement in the following cases:

- raft foundation (lightweight structures)

- structural concrete

- base slab

- sidewalk

- driveway

- pavement

- pits

- ground-level stairs

The advantages of structural macro fibers

- In 3 dimensions, it reinforces concrete at every point, while mesh reinforcement operates in only one plane.

- It reduces shrinkage cracks to zero. This means that no cracks, big or small, can form during the concrete curing process, resulting in a much more durable concrete.

- It significantly speeds up construction by replacing processes associated with mesh reinforcement.

- It enhances safety at work by eliminating accidents associated with the use of mesh reinforcement.

- It’s easy to transport. We can replace 500 kg of mesh reinforcement with 25-50 kg of ArmoTec, which can be delivered to your doorstep by a mail carrier instead of a truck.

- It’s easy to work with. Just add it directly to the concrete mixer; no transportation, no handling, no rebar assembly, no hassle.

- It does not corrode. One of the biggest disadvantages of reinforced concrete is that over time, the enclosed steel begins to corrode due to acids. Oxygen and moisture penetrate the concrete’s tiny microcracks, causing it to deteriorate. ArmoTec completely eliminates this problem.

- It’s easy to drill fiber-reinforced concrete, with no drill breakage.

- It’s much cheaper than mesh reinforcement.

- It leaves a much smaller ecological footprint. Its production and transportation result in a fraction of the environmental pollution caused by steel reinforcement. Furthermore, by replacing steel with ArmoTec, you can reduce the amount of corrosion-resistant concrete needed, making a significant contribution to environmental protection. If environmental conservation is important to you, then this is your material.

- Scientific studies support its significant reinforcement effect on concrete and even suggest it could replace steel reinforcement.

- At least 50% of concrete structures are used to protect steel reinforcement from corrosion. With macro fibers, this is unnecessary, significantly reducing the amount of concrete needed.